BYD Blade Battery — WMS Scheduling for Automated Production

- david david

- Mar 4, 2025

- 1 min read

Project Scope

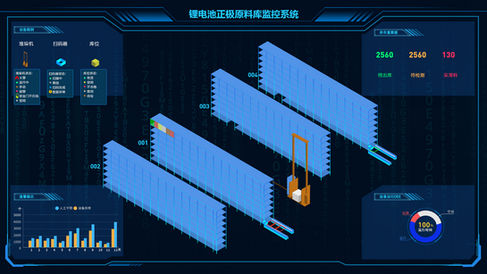

QWmind Tech delivered a Warehouse Management and Scheduling (WMS) solution tailored for a BYD blade-battery production line. The scope covered real-time WMS scheduling, equipment and logistics-line monitoring, task dispatch to automated handling systems, and full traceability across production stages — from incoming material allocation to finished-goods staging.

The Challenge

The customer needed tighter control over product status and better visibility into equipment utilization across a highly automated production flow. Existing systems produced fragmented status data, which hindered rapid decision-making, increased the time required for product handovers, and limited the ability to optimize line balance and resource allocation during peak ramps.

Our Solution

We implemented a purpose-built WMS scheduling layer that acts as the operational conductor between MES, automated material handling, and the plant’s robotics/AGV fleet:

Scheduling Engine: Dynamic task prioritization and load-aware dispatching that adapts to real-time line conditions and downstream constraints.

Real-time Visibility: Live dashboards and event streams reporting equipment state, queue lengths, and material location for operations and maintenance teams.

Seamless Integration: Bi-directional interfaces with the client’s MES and equipment controllers to ensure consistent product state, automatic handoffs, and synchronized process timing.

Operational Safeguards: Automated exception handling for process deviations, with guided recovery workflows to minimize unplanned stoppages.

The Outcome

The WMS scheduling deployment delivered immediate operational benefits: improved clarity of product state across the line, faster handover between process stages, and more balanced equipment utilization. By centralizing scheduling decisions and surfacing actionable, real-time data, the system reduced qualification friction during pilot runs and enabled smoother, faster transitions to steady production. Overall, BYD gained a more predictable, controllable, and scalable production environment for its blade-battery line.